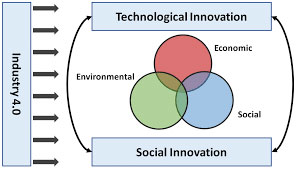

Industry 4.0 and Agriculture 4.0

Industry 4.0, also called the Fourth Industrial Revolution, is the most popular phenomenon of the moment in terms of innovation

ENVIRONMENT & SAFETY ENGINEERING

INDUSTRY 4.0 - Industry and future

Industry 4.0, also called the Fourth Industrial Revolution, is the most popular phenomenon of the moment in terms of innovation. Let's find out what it is and why it is so important for companies to reap the benefits and keep up with the times.

Industry and future

The industrial ecosystem is undergoing a real transformation. A wave of innovation is spreading forcefully and quickly among the production systems operating all over the world: we live in the middle of an industrial revolution, the fourth.

This revolution, compared to the previous ones, sees as protagonist the use within the production plant of enabling technologies called KET (Key Enabling Technology), solutions or technological improvements, that is, which contain a lot of research and development activities. and they are able to “revitalize the production system”.

This means that by exploiting these solutions, industry-related processes will be equipped with a fast, clear and direct interconnection between all corporate assets.

Productivity increases, wate decreases.

The enabling technologies that conventionally characterize industry 4.0 are:

- Advanced robotics

Interconnected machines, rapidly programmable and equipped with artificial intelligence - Additive manufacturing

3D printing, digital fabrication - Augmented reality

Wearable devices through which to experience a plane of reality superimposed on our own - Horizontal / vertical integration

All the steps of the value chain, from producer to consumer, communicate with each other - Simulation

Ability to simulate new processes related to production before putting them into practice in reality - Industrial Internet or Internet of things applied to industry

Recognizable and intelligent objects ("things") able to communicate data about themselves - Cloud

Management of large amounts of data directly on the network - Cyber-Security

guarantee of security during network operations and on cloud systems - Big Data and analytics

Analysis of a large database of data necessary for the real-time production of useful information to optimize products and production processes

The implementation of these new technologies requires a paradigm shift. We are facing a transition: from the old concept of factory to the new intelligent factory "Smart Factory", characterized by a digitized production, which works dynamically by means of a "brilliant" manufacturing, composed of more fluid processes, interconnected, and by production systems adapted to modernity and its needs, capable of making the best use of available resources.

PRODUCE MORE WITH LESS WASTE

This is the philosophy of INDUSTRY 4.0

Briefly, we can say that the fourth industrial revolution is characterized by the introduction into the production system of intelligent machines, interconnected and connected to the internet, which allow complex analyzes through Big Data and real-time adaptations.

But let's see concretely what are the benefits of the revolution that is overwhelming the production ecosystem right now:

- Greater flexibility through the production of small batches at large scale costs

- Faster speed from prototype to mass production through innovative technologies

- Increased productivity through shorter set-up times, reduced errors and downtime

- Better quality and less waste thanks to sensors that monitor production in real time

- Greater competitiveness of the product thanks to greater features deriving from the Internet of Things

By connecting all the assets involved in the logistics-production chain, the primary advantage of the Industry 4.0 paradigm is certainly the availability of all relevant information in real time. Obtaining the reporting and support necessary to overcome any production bottlenecks from the data at any time is not an aspect to be underestimated. The connection between people, things and systems creates enormous added value in terms of cost reduction, availability of information in real time and interaction between resources.

Not surprisingly, companies that have already introduced enabling technologies within their PLANT estimate a growth in production efficiency of 30-50% thanks to the use of new technologies.

AGRICULTURE 4.0

Precision agriculture

The 2020 - 2021 Budget Laws provide for the possibility for agricultural businesses to benefit from the tax incentives, reliefs and concessions introduced by the National Business Plan 4.0.

Agriculture 4.0 is the evolution of the concept of "precision agriculture" which is used to define targeted and efficient interventions in the agricultural field starting from data such as, for example, the physical and biochemical characteristics of the soil. In fact, it is the whole set of tools and strategies that allow the farm to use advanced technologies in a synergistic and interconnected way with the aim of making production more efficient and sustainable.

In practice, adopting 4.0 solutions in the agricultural field includes, for example, being able to accurately calculate the water requirement of a given crop and avoid waste. Or, it allows you to predict the onset of certain plant diseases or identify pests in advance that could attack crops, effectively reducing waste.

Another area of application of agriculture 4.0 is that of the traceability of the supply chain and, according to insiders, this is where the most interesting prospects can be glimpsed looking to the future. During each step, from the field to the packaging, it is possible to collect useful data to keep every step of the production process under control.

Little margin for error, therefore, makes it possible to create a short supply chain capable of producing food of the highest quality and in an environmentally sustainable manner.